LTLT Pasteurization Machine

Technical Specifications:

- All contact surfaces are made of stainless steel A3.4 or A316.

- Equipped with a cooling unit.

- Equipped with a plate heat exchanger.

- Equipped with a gas or electric heater.

- Suitable dimensions.

- Easy to clean.

- Efficient operation.

- Minimum cooling capacity: 1 ton of refrigeration.

- Minimum milk capacity: 20 liters.

- Outer wall of the tank is made of stainless steel A304.

- Ice maker water temperature: 2°C.

- Polyurethane thermal insulation.

Description

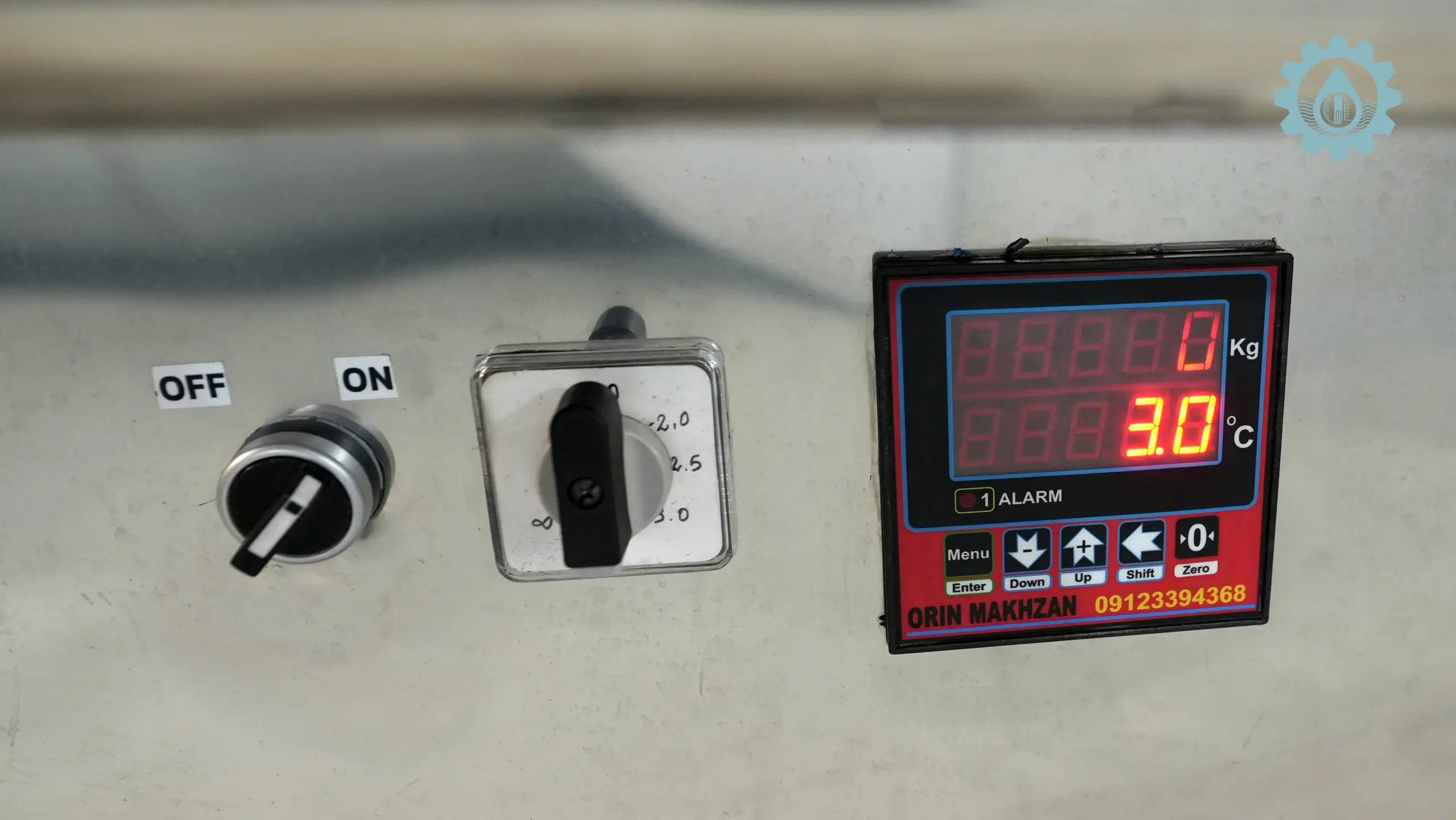

Orin makhzan's LTLT Pasteurization Machine and Its pros

It’s a method of pasteurization of raw milk: In this method the temperature of raw milk will increase into 63 c and it will stay for 30 min. We offer this type of Pasteurizer for dairy farms which have less than 250 dairy cows and its affordable for them because it can perform 4 operation simultaneously such as pasteurize the raw milk, It's a taxi milk, It can keep the milk warm and individuals can control the amount of milk which is consume by calves in addition dosing unit also measure the milk temperature in order to feed the calves with optimum temperature. Easy milk transportation has the great help for our customers. the advantage of using dosing unit is that manager of dairy farm can control the amount of milk which is consume every day by calves in order to reduce changes the DM intake by the calves.

Hence, it not only can reduce diarrhea but also improve ADG in calves and it also has a agitator that heats the milk evenly, if some additives are added to the milk, it can dissolve evenly. One of the most important points to be considered is that this machine performs pasteurization without wasting water. This machine will pasteurize raw milk up to 200 L. Since the cover can be fully opened, cleaning of the tank is extremely easy, and individuals can wash it manually.

Reviews

There are no reviews yet.