Colostrum Pasteurizer

Technical Specifications:

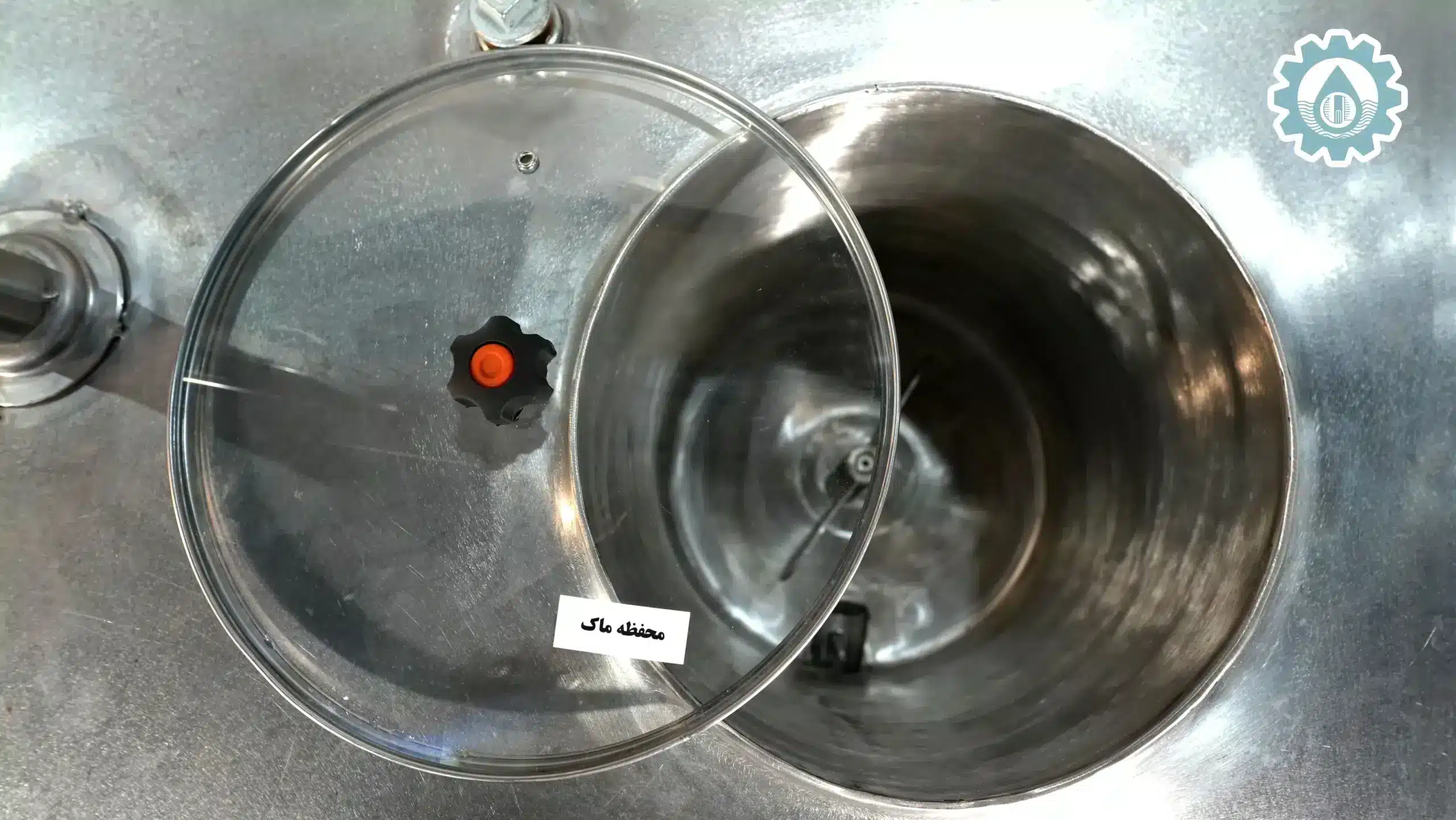

- All contact surfaces are made of A3.4 or A316 stainless steel.

- Equipped with a cooling unit.

- Equipped with a plate heat exchanger.

- Equipped with a gas or electric heater.

- Suitable dimensions.

- Easy to clean.

- Efficient operation.

- Minimum cooling capacity: 1 ton of refrigeration.

- Minimum milk capacity: 20 liters.

- The outer wall of the tank is made of A304 stainless steel sheet.

- Freezer water temperature: 2°C.

- Polyurethane thermal insulation.

Description

Colostrum Management

Passive immunity is the only source of early immunity for calves due to the inability of the bovine placenta to transmit maternal immunoglobulins to the fetus. Hence, consuming colostrum is vital for calves during the first hours of life . The immune status of calves during the preweaning period depends directly on the quality and quantity of colostrum ingested during the first hours of life. Newborn dairy calves rely on timely ingestion of high-quality colostrum with low bacterial contamination to transfer passive immunity (TPI) as well as nutrients and other bioactive components. Poor TPI in calves has been associated with lower ADG, a greater risk for preweaning morbidity and mortality, and a lower likelihood to reach first insemination and calving.

What kind of colostrum should be fed to the calves, and which colostrum should be saved?

Research shows that high-quality colostrum has a Brix value ≥ 22%, which means that it has more than 50 g of IgG per L. It is recommended that calves be fed 10% to 12% of their body weight (BW) of colostrum at first feeding, it is vital to receive 200 g of IgG within the first 6 h after birth to increase the likelihood of a successful passive transfer of immunity. Colostrum with a Brix percentage of more than 22 should be stored in order to consume for calves whose mothers do not have high-quality colostrum.

Why colostrum should be pasteurized?

Colostrum pasteurization is a very effective method to reduce the total bacteria count with minimal effect on IgG concentration at 60 °C for 60 minutes because increasing the amount of bacteria, whether environmental or mammary, can reduce the absorption of IgG. According to research by pasteurization of colostrum, absorption of IgG will increase by 11.5%, and also, according to the research, it was evaluated that pasteurized colostrum at a temperature of 60 °C for 60 minutes destroys live infectious agents of Mycoplasma bovis (108 cfu/mL), Listeria monosogenes (106 cfu/ml), Escherichia coli (106 cfu/ml), and Salmonella enteritidis (106 cfu/ml).

What are the methods of colostrum pasteurization?

It has been established that heating colostrum at 60 °C for 30 to 60 or 90 min can be a good treatment to maintain colostrum quality and significantly reduce important pathogens that can contaminate it, such as Listeria monocytogenes and E. coli. Any increase in temperature above 60 °C results in a significant decrease in IgG.

Pros of Orin Makhzan Colostrum Pasteurizer

The Orin Makhzan colostrum pasteurizer machine is divided into 3 compartments, which include: colostrum pasteurizer, freezer (up to -18°C), and Ben Marie. Due to the importance of all 3 steps, the Orin Makhzan company has made a machine with the mentioned capabilities. Due to the fact that keeping colostrum at room temperature increases the amount of bacteria. Hence, every 20 minutes, keeping colostrum at room temperature doubles the colony of bacteria; because of that, it is recommended to freeze colostrum immediately after milking. On the other hand, to melt colostrum, the temperature should not exceed 60 °C. Increasing the temperature above 60 °C to melt the colostrum will destroy the immunoglobulins, and then the passive immunity will not be properly transferred to the calves and cause the failure of the passive transfer immune, so we made a machine with Bain Marie in order to melt colostrum at the optimum temperature.

Reviews

There are no reviews yet.