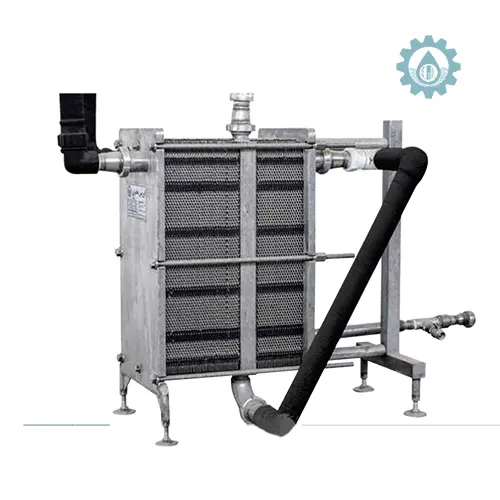

Heat Exchanger

Category: husbandry-machines

Description

Description

The Application of Plate Heat Exchangers in the Dairy Farming Industry

Plate heat exchangers are crucial equipment in the dairy farming industry, playing a vital role in improving efficiency and product quality. Due to their compact design, high efficiency, and energy-saving capabilities, these heat exchangers are used in various processes within dairy farms. Below are some of the key applications of plate heat exchangers in the dairy farming sector.

- Milk Pasteurization in Dairy Farms.

One of the essential processes in milk production is pasteurization, which aims to eliminate harmful bacteria and extend the shelf life of raw milk Plate heat exchangers, with their effective heat transfer capabilities, rapidly raise the temperature of milk to the desired level and then cool it down quickly to preserve its quality and freshness. This process ensures high-quality milk and reduces the risk of contamination. - Rapid Cooling of Freshly Milked Milk

Freshly milked milk needs to be cooled immediately to prevent the growth of microorganisms and preserve its quality Plate heat exchangers are designed to quickly reduce the temperature of milk. These heat exchangers use cold water or cooling solutions to absorb heat from the milk, allowing it to cool rapidly and be ready for storage in refrigeration tanks. - Heating Water for Cleaning and Hygiene

Hygiene is of utmost importance in dairy farming. Regular cleaning of milking equipment, storage tanks, and the environment where cows are kept is essential to prevent contamination and maintain milk quality. Plate heat exchangers, known for their efficient water heating capabilities, quickly heat water to the appropriate temperature for washing and disinfection This helps reduce energy consumption and enhance overall hygiene. - Biogas Production and Heating Supply

In many dairy farms, animal manure is used to produce biogas, a renewable energy source. Plate heat exchangers play a significant role in the biogas production process by transferring the thermal energy generated to heating systems This energy can be used for heating water, warming cow barns, and powering other farm operations, contributing to reduced energy costs. - Temperature and Humidity Control in Cow Barns

Controlling the temperature and humidity in cow barns is essential for maintaining cow health and increasing milk production efficiency. Plate heat exchangers are effectively used in HVAC systems to regulate temperature and humidity. These exchangers provide efficient heat exchange, creating a more comfortable environment for cows to thrive and produce better.

Advantages of Using Plate Heat Exchangers in Dairy Farming

High Efficiency: The large heat exchange surface area in plate heat exchangers enables faster and more effective heating and cooling processes.

Reduced Energy Consumption:

These exchangers help lower energy costs while increasing process efficiency.

Compact Design: The compact design of plate heat exchangers occupies less space, making them easier to install in dairy farm facilities.

Easy Cleaning:

The detachable plates allow for easy cleaning, which is crucial for maintaining hygiene in milk processing.

Long Lifespan and Low Maintenance:

Made from corrosion-resistant materials, these exchangers have a long service life and require less maintenance.

Conclusion

With their high efficiency and advanced design, plate heat exchangers have become essential tools in the dairy farming industry. These devices help improve product quality, enhance operational efficiency, and reduce costs If you are looking for effective solutions to optimize heat processes in your dairy farm, plate heat exchangers can be an excellent choice.

For more information and expert consultation, please contact us.

Reviews (0)

Be the first to review “Heat Exchanger” Cancel reply

Reviews

There are no reviews yet.