Chiller (for raw milk)

Technical Specifications:

- Frame made of structural steel or stainless steel.

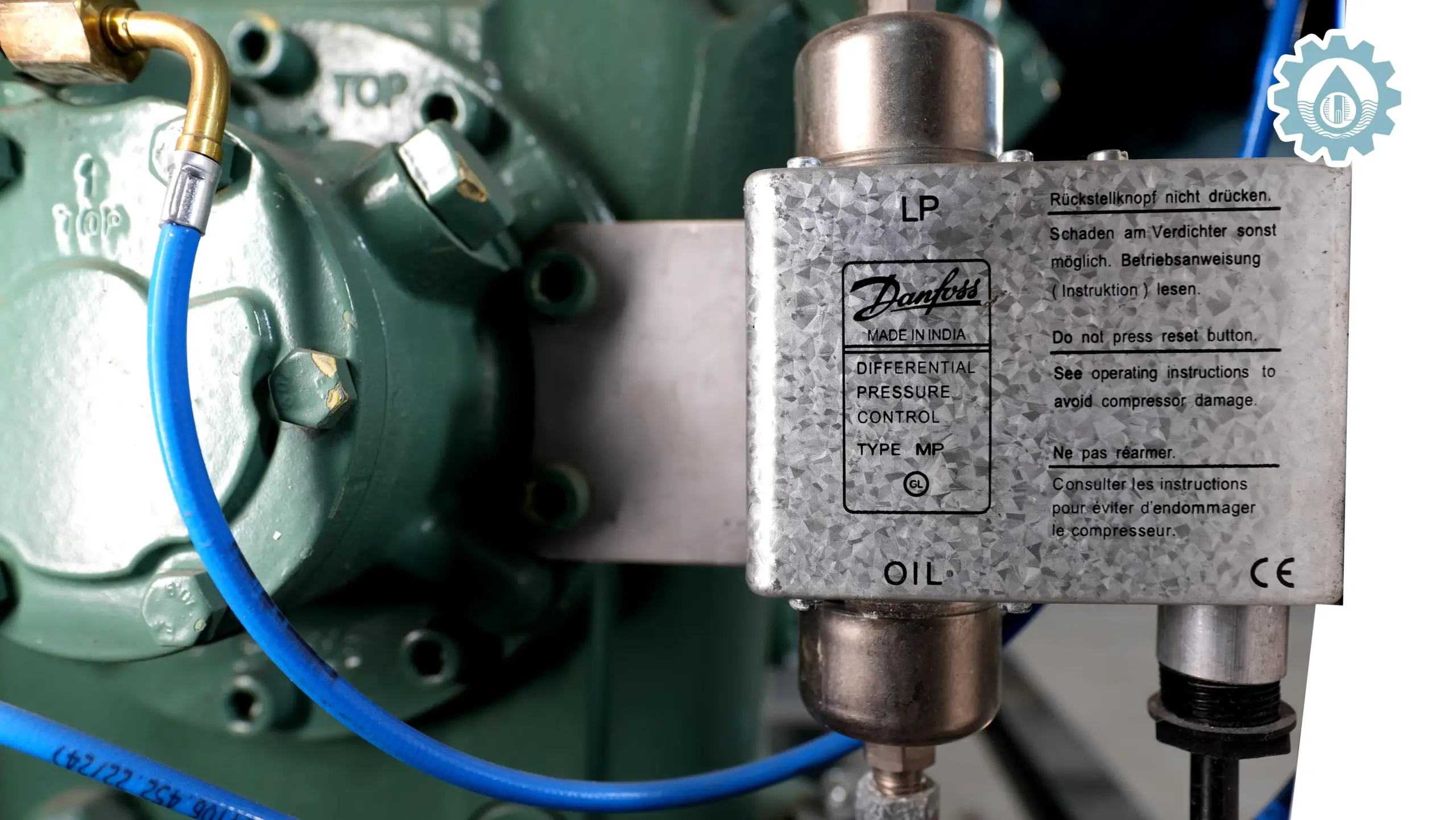

- Compressor from reputable brands such as DWM, Bitzer.

- Air-cooled condensers from well-known local brands.

- Evaporators are of the shell-and-tube or plate type.

- Equipped with a control panel.

Description

Introduction to the Chiller (Specialized for Cooling Raw Milk)

Using of Chiller for raw milk

Chilling raw milk immediately after milking is a critical step in preserving its quality and safety. The temperature of milk naturally rises after milking, providing an ideal environment for the growth of bacteria. By rapidly cooling the milk to around 4°C (39°F) or lower, the growth of these microorganisms is slowed significantly, thus extending the shelf life of the milk and maintaining its freshness.

The effects of chilling on raw milk include:

- Reduction in Bacterial Growth: Bacteria, especially spoilage organisms like Lactobacillus and Pseudomonas, proliferate rapidly at temperatures above 10°C (50°F). Chilling the milk quickly to a lower temperature reduces the rate of bacterial reproduction, helping to maintain the milk’s safety and prevent souring or the development of off-flavors.

- Preservation of Nutritional Quality: High temperatures can denature proteins and degrade vitamins in milk, especially sensitive ones like vitamin C. By chilling the milk quickly, these nutrients are better preserved, ensuring the milk remains nutritionally rich.

- Improved Milk Quality: Chilling slows down enzymatic activity that could otherwise lead to undesirable changes in milk, such as increased acidity or altered flavor. This helps maintain the milk’s desirable taste and texture.

- Prevention of Spoilage: Chilled milk is less prone to spoilage by both bacteria and enzymes. This helps in preventing the development of off-smells, sourness, or curdling that can occur when milk is left at higher temperatures for extended periods.

- Compliance with Food Safety Standards: In many dairy-producing regions, there are strict regulations regarding the temperature control of raw milk to ensure that it meets health and safety standards. Chilling is an essential part of the process to comply with these regulations and to reduce the risk of milk-borne diseases.

In summary, chilling raw milk immediately after milking is a vital practice for maintaining milk’s quality, ensuring its safety, and extending its shelf life. The benefits of this process are seen in reduced bacterial growth, improved flavor, and preserved nutritional value, all of which are essential for both consumers and producers in the dairy industry.

Reviews

There are no reviews yet.